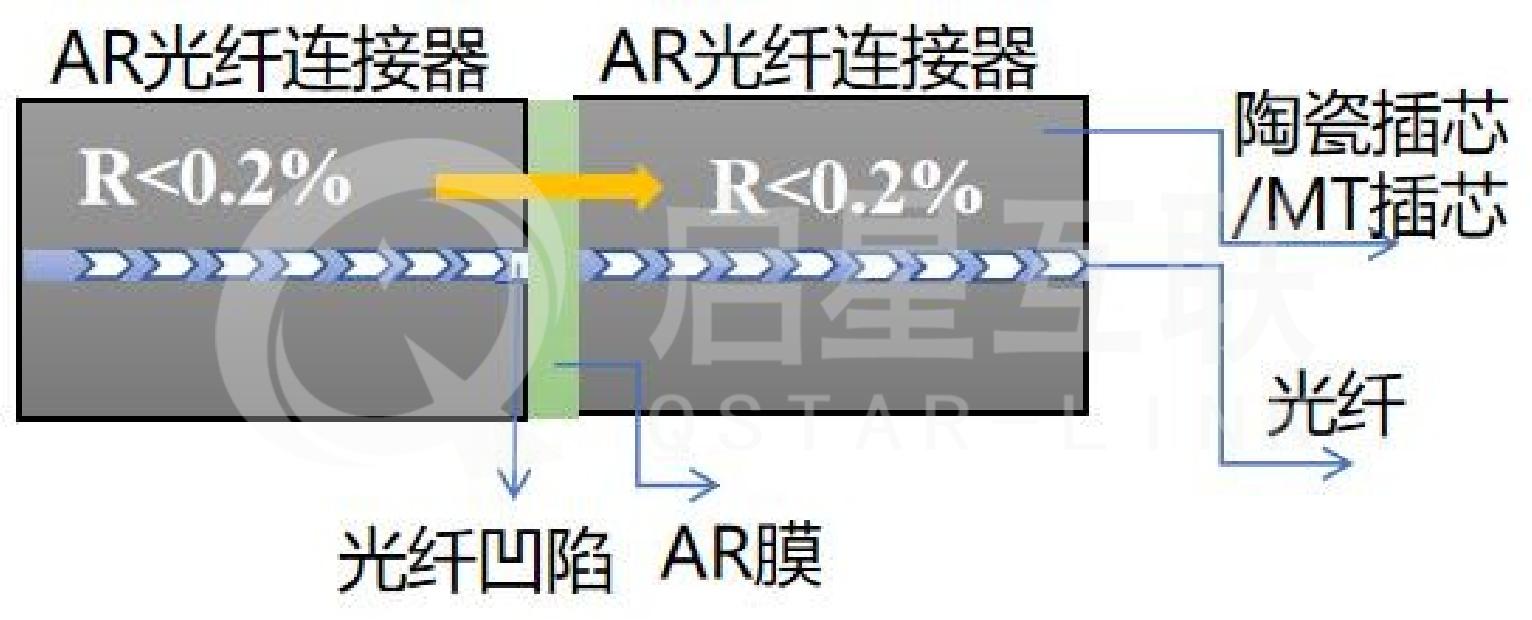

AR Fiber Optic Connector achieves optical signal transmission through a specially designed optical structure (fiber concave grinding+end face coating), avoiding direct physical contact between fiber end faces.

Working principle of AR fiber optic connector

Ordinary fiber optic connector

Due to the limitations of mechanical alignment accuracy and interface Fresnel reflection (R ≈ 4%), the residual optical field forms a Fabry Perot cavity effect between the end faces, causing insertion loss fluctuations and echo interference, which are rooted in nanoscale air gap defects and waveguide mode mismatch.

AR fiber optic connector

Unlike ordinary fiber optic connectors, AR fiber optic connectors do not have direct contact between the fiber end faces during docking. MT plugs eliminate the reflection between the two interfaces by plating AR film on the end faces, thereby eliminating the resonant cavity and greatly eliminating the interference of resonance and reflection. There is a certain air gap between the end faces, which can protect the fiber optic end faces of the connector from damage.

Product advantages

1. Not sensitive to dirt and stains

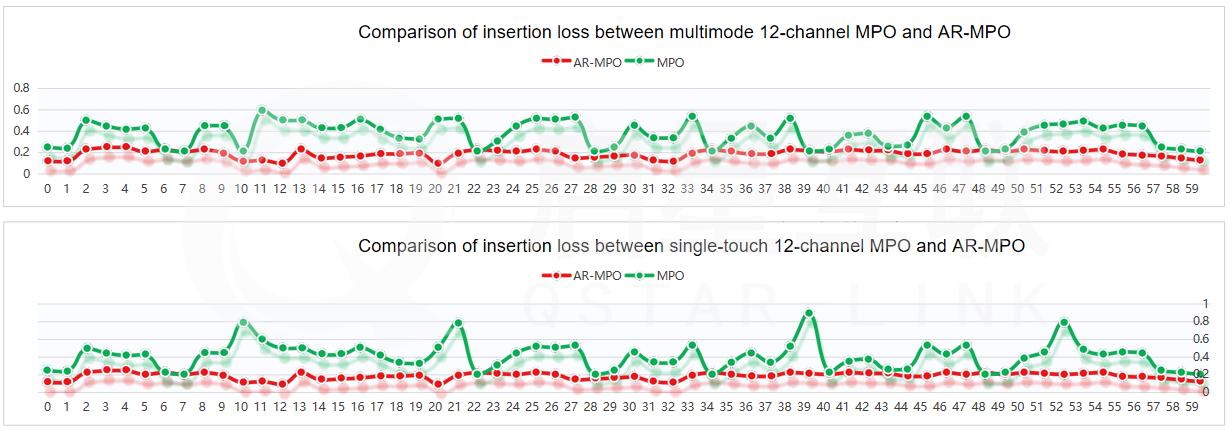

2. Good random interoperability

3. Good repeatability in plugging and unplugging

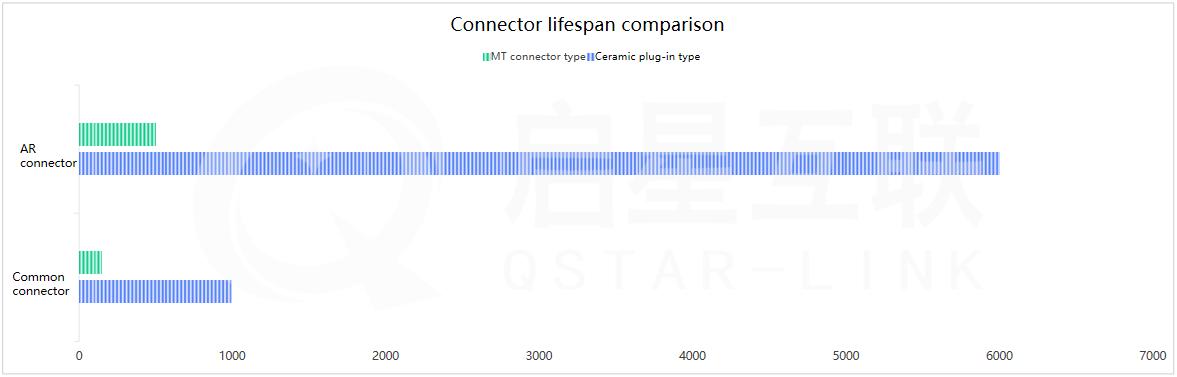

4. Long plug-in life

5. Protect the end face of the tested device

Cleaning methods for AR fiber optic connectors

Soak an appropriate amount of high concentration ethanol in a microfiber cleaning cloth and lightly press it onto the fiber end face for unidirectional cleaning to avoid back and forth friction.

.png)

.jpg)

.png) Add:F3 Floor, Building 1, Good Luck Fashion Industry Park, No.1 Langben Road, Xinshi Community, Dalang Street, Longhua District, Shenzhen

Add:F3 Floor, Building 1, Good Luck Fashion Industry Park, No.1 Langben Road, Xinshi Community, Dalang Street, Longhua District, Shenzhen  Tel:0755-23772684

Tel:0755-23772684 Inquery:wing@qstar-link.com

Inquery:wing@qstar-link.com.png) Technical Support:roy@qstar-link.com

Technical Support:roy@qstar-link.com